Diesel engines have been widely used for commercial vehicles such as buses or trucks, but currently, there are quite a few private vehicles such as SUVs that already use diesel engines because the torque generated is quite large and uses the Internal Combustion Engine (ICE) as fuel.

One of the main differences with gasoline-powered engines is that there is no need for a lighter to create combustion, so a diesel engine does not need a spark plug. Diesel engines use compressed air and diesel to create combustion.

History

The diesel engine was invented by Rudolf Diesel, a German engineer who was born in France in 1858. His German parents migrated to France.

Rudolf Diesel has conducted research to find out how to efficiently use fuel in engines. Because in his day most machines still used steam engines with an efficiency level of 10-15%.

In this research, Diesel designed an engine whose fuel is sprayed into the compression chamber. The heat generated by compression will then burn the fuel that has been mixed with air.

This machine is what became known as a diesel engine, as well as answering Diesel's dream to create an engine with a high level of efficiency because the fuel used for diesel engines is residual oil from the gasoline filtering process.

Along with technological developments, fuels for diesel engines now use biofuels such as jatropha oil. Diesel’s invented engine is quite revolutionary because it no longer uses fossil fuels such as gasoline.

How The Diesel Engine Works

Baca Juga

Quite similar to a gasoline engine, the combustion process in a diesel engine can go through two steps (2 strokes) and four steps (4 strokes). However, what is widely used today is a 4 stroke diesel engine.

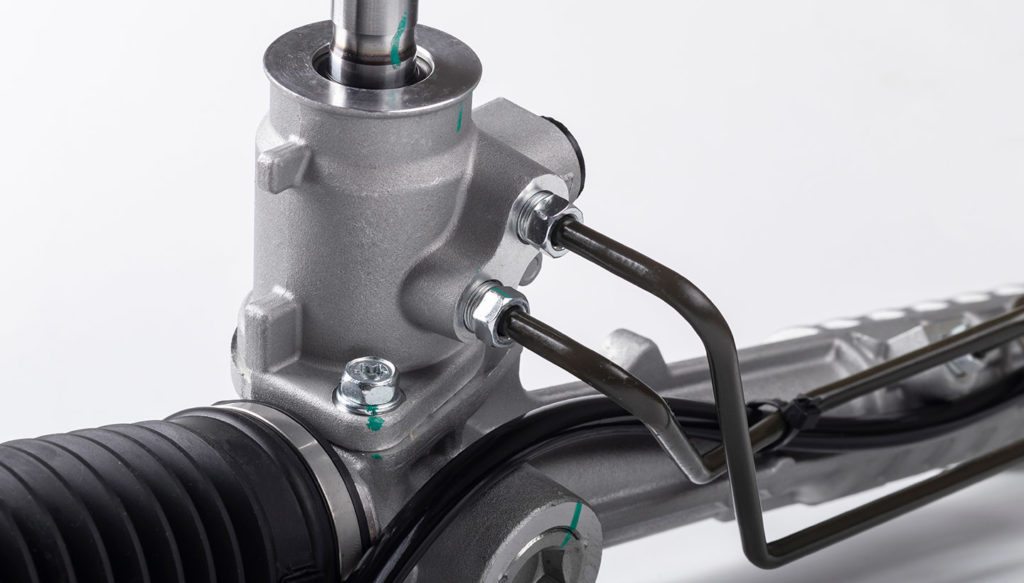

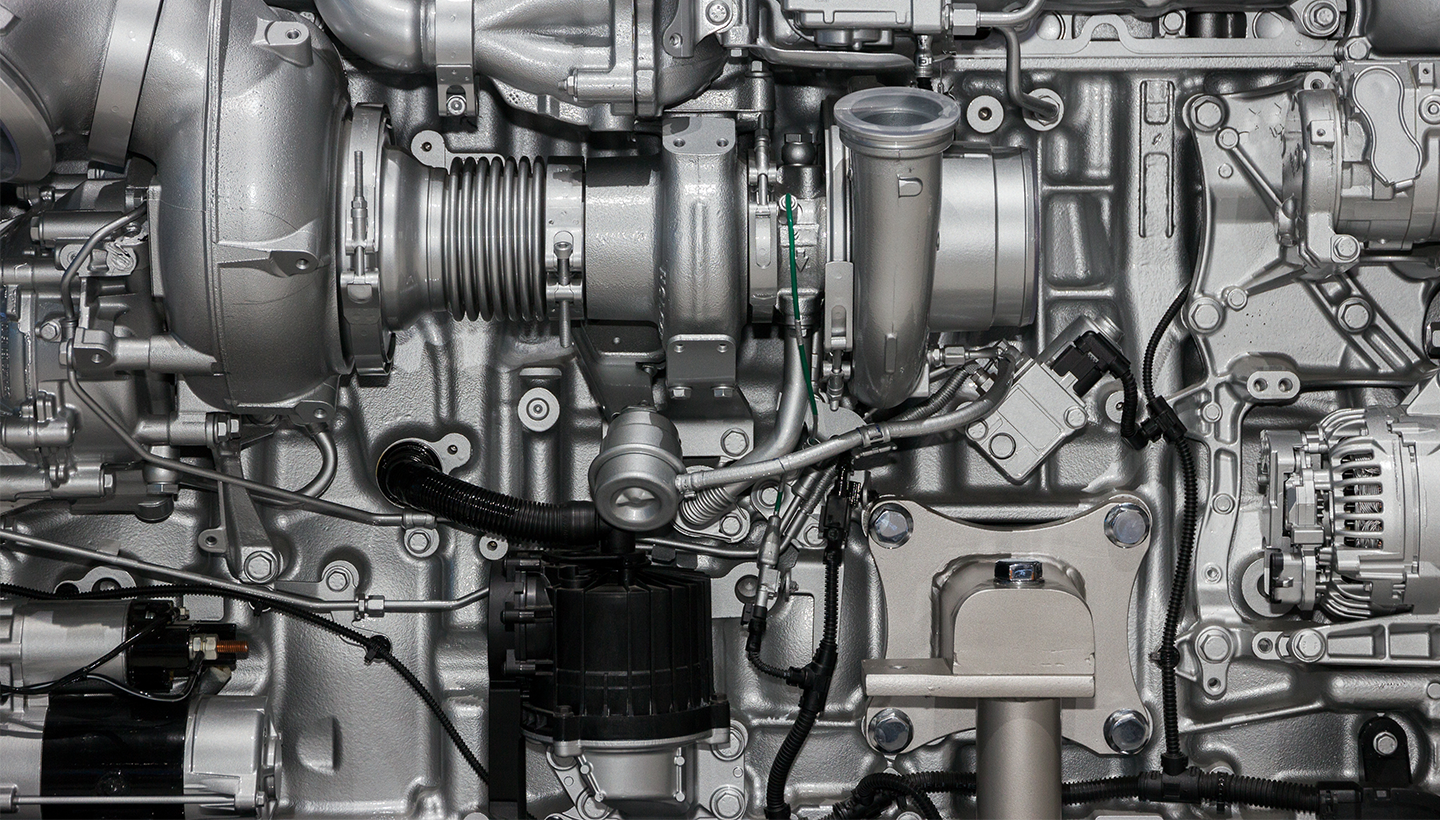

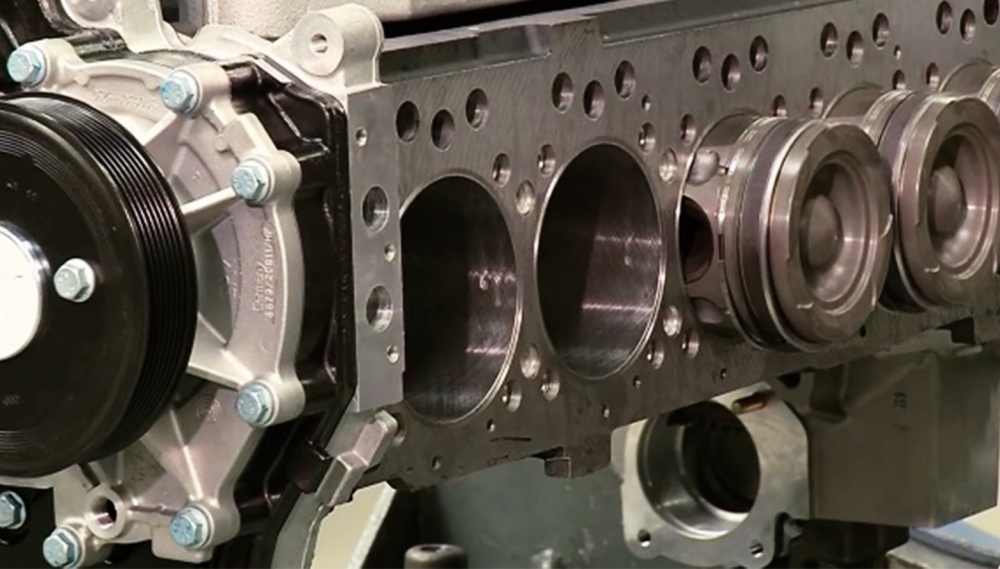

There are several components in a 4 stroke diesel engine, namely the piston, cylinder head, cylinder block, suction valve, intake manifold, exhaust valve, exhaust manifold, and injector. The following are the stages of how a diesel engine works:

- Suction step. In this process, the piston will move from the top dead center (TDC) to the bottom dead center (BDC) and cause the combustion chamber to expand. In this process, air will enter the combustion chamber in the intake manifold through the open suction valve.

- Compression step. The piston will move from the bottom dead center (BDC) to the top dead center (TDC). To create compression, the intake and exhaust valves will be tightly closed and the piston movement will compress the air in the combustion chamber. The result is that the pressure and temperature will increase.

- Work step. This starts taking effect when the piston is at the top dead center (TDC) and the air pressure is at the highest point. At this time, diesel fuel will be sprayed from the injector to the combustion chamber and the result will be the diesel fuel burned by the air temperature that is already above the diesel fuel point. The result of this process will create the piston pushing force to the bottom dead center (BDC).

- Exhaust step. In this process, the piston will move from the bottom dead center (BDC) to the top dead center (TDC) in the condition that the exhaust valve opens and removes the remaining combustion gas. When finished, the process starts all over again from step 1 and onward.

Diesel Engine Type

Three types of diesel engines are currently used in car engines, namely:

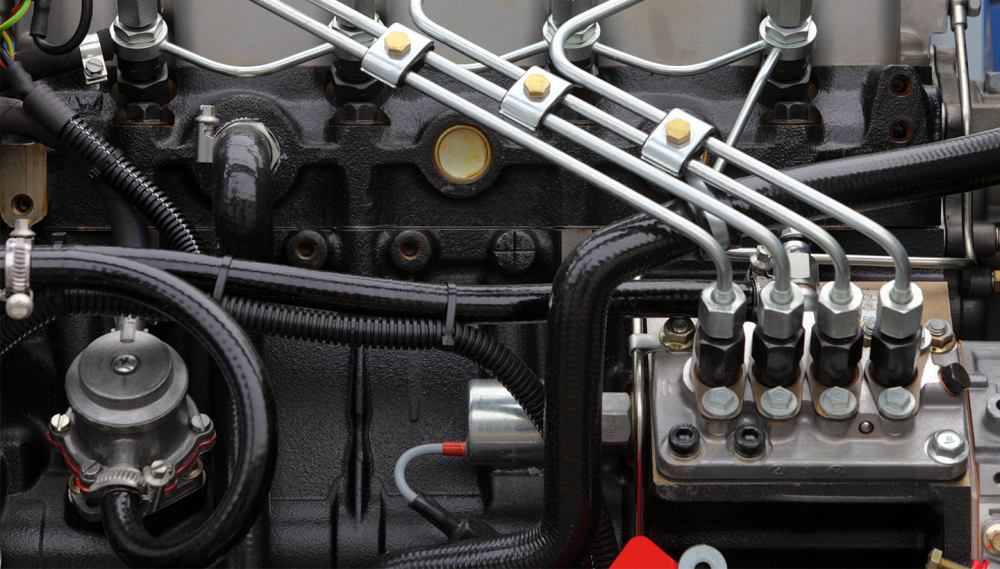

1. Indirect Injection Diesel (IDI)

Indirect injection diesel engines have been widely used in diesel car engines with low capacities of below 3,000 ccs, such as small trucks, SUVs, or medium commercial cars. This engine has two combustion chambers.

The first one is the "main combustion chamber" which is located above the piston. The second one is the "pre-combustion chamber" which is located in the combustion chamber. Both are connected by a channel.

Combustion occurs in the "pre-combustion chamber" because there is an injector inside. After combustion occurs, the gas will be burned in the "main combustion chamber" which is located above the piston.

However, this type of diesel engine is no longer used in the latest production diesel engines as its efficiency and emissions are not very good. The difference with other types of diesel engines is the presence of glow plug components that are always present in Indirect Injection type diesel engines.

2. Direct Injection Diesel (DI)

Baca Juga

Direct Injection diesel engines are considered to be better than the previous type due to its more practical design. It has only one combustion chamber located in the hollow above the piston. This type of diesel engine does not require glow plugs and the injector will be directly inserted into the combustion chamber through the upper cylinder head.

Compared to the previous type, the Direct Injection diesel engine has much better and more efficient power and better quality of emissions. The difference with other types of diesel engines is the location of the injector which is located in the center of the cylinder head. In general, cars such as large trucks or buses already use this Direct Injection diesel engine.

3. Common Rail Direct Injection (CRDI)

Common Rail Direct Injection (CRDI) diesel engines are the latest technology that has begun to be used in the latest SUVs. Usually marked with a CRDI or VCDI label sticker affixed.

Unlike the two types mentioned above, the CRDI work system is similar to the EFI system on a gasoline car, using computer-based technology to determine the volume of diesel from the injector.

Similar to Direct Injection, the CRDI engine uses one combustion chamber with the injector which is located directly above the piston. This type of diesel engine uses glow plugs. The difference with other types of diesel engines is the presence of a fuel rail component, which is an iron pipe connected to all the injectors. The fuel rail is located near the injectors.

The latest diesel car already uses this technology, because it has many advantages such as very economical fuel, large power, and emissions pass EURO 3.

Advantages of Car Diesel Engines

Longer engine life

In general, diesel engines are made using materials that are stronger than gasoline engines, because the compression is also higher. The temperature in the combustion chamber is much hotter than a gasoline engine because it has to burn diesel at the maximum temperature.

High torque

The torque produced by a diesel engine is much better at low rpm. The comparison is that a four-cylinder diesel engine is capable of producing the same torque as a six-cylinder petrol engine, although the horsepower output tends to be smaller.

Economical

The main advantage of a diesel engine over a gasoline engine is fuel consumption. Thanks to the high compression ratio, diesel engines consume less than gasoline engines. The price of fuel is also easier than gasoline.

Compatible with alternative fuels

In contrast to gasoline engines, diesel engines can be used with the latest fuels without major modifications.

Simple Mechanics

Another difference with a gasoline engine is its simplicity. The latest technology gasoline engine uses fuel injection and sophisticated spark plugs and uses an ECU. Meanwhile, the mechanical diesel engine is much simpler and, hence, is easier to maintain

Disadvantages of Car Diesel Engines

Noisy

Noise generated by a gasoline engine comes from the exhaust or exhaust system. In a diesel engine, a noise comes from the engine and we can even hear it easily so the damping system on the hood must be more complex than a gasoline engine.

Expensive

The compression ratio produced by a diesel engine is much higher, so the material used is much stronger than a gasoline engine. As a result, the price is also higher than the gasoline engine.

SHARE: